Innovative startup Space Foundry has discussed what the next big step in 3D printing could be, namely plasma printing.

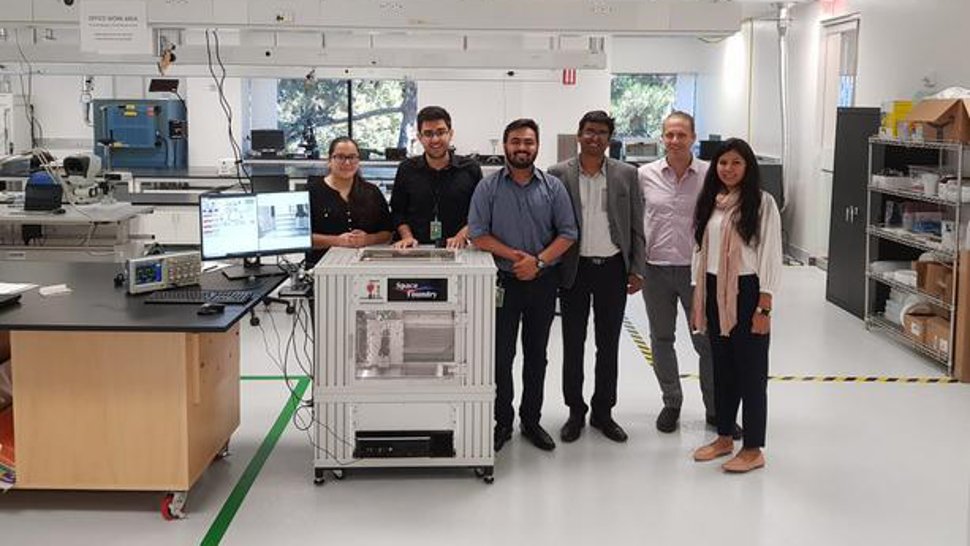

Space Foundry was designed by Ram Prasad Gandhiraman and Dennis Nordlund, and the plasma printing is the culmination of three years of hard work.

Whereas 3D printing, in simple terms, simply creates plastic objects (from filaments), a plasma print head modifies the material as it is made, with "an integrated fluid distribution design (which allows mixing various liquid precursors and gas mixtures") - multi-material printing.

So, for example, instead of just printing objects, a plasma-based device can produce chips printed on a glass surface, for example. This could be potentially revolutionary for the Internet of Things in terms of the use of glass-based circuit boards.

Nordlund's enthusiasm: "Imagine tomorrow, the display screen should not exist in a car; the windshield can be a device that transmits information. The world has endless possibilities with this new form of printing."

Defying weightlessness

And not just the world, but beyond. A plasma printer can print on any surface and could play a big role in the ability to print in space (the lack of gravity is an obvious and extremely delicate challenge for the humble 3D printer).

So how much does one of these plasma printers cost? As Your Story reports, Space Foundry sells a standalone printer for more than € 100,000 and has fulfilled orders from six customers, including NASA.

The startup also received a € 2.5 million grant from NASA, clearly underscoring the potential of plasma printing in space.

Ultimately, the project of this Silicon Valley-based startup is to offer a short-term production and contract development service later in 2020. Once more than 100 plasma printers are sold, the company also plans High visibility and advertising with a full marketing team.